The late 19th century brought a revolution in stage mechanics, as hydraulic and electric power was used for the first time, enabling far larger and heavier machinery than could be operated by human power alone.

In the 1880s, there was a desire for new stage machinery that could support, on the one hand, naturalist drama, with its complete, realistic, three-dimensional scenery filling the stage, and on the other hand spectacle, with its appetite for ever more extraordinary stage effects. There was also a strong motivation to make stages safer by moving from inflammable wood to metal construction. At the same time, the industrial revolution made available several key technologies: hydraulics, steel and electricity.

Hydraulic systems, using water or another fluid to transmit power, were known to the Greeks of Antiquity, who developed complex systems of water and hydraulic power. The Frenchman Blaise Pascal discovered the principles of hydraulics, which led to his invention of the hydraulic press, in which a smaller force acting on a smaller area is transferred to a larger force acting over a larger area, transmitted through the same pressure at both locations. Joseph Bramah patented the hydraulic press in 1795, beginning the industrial application of hydraulics, which developed over the course of the 19th century. In 1856 Henry Bessemer developed a new method of steel-making. The Bessemer process greatly reduced the cost of steel production, making it available as a construction material in the second half of the 19th century. In the same time period, numerous scientists and engineers contributed to the development of the electric motor.

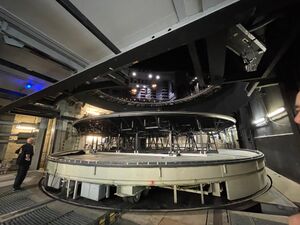

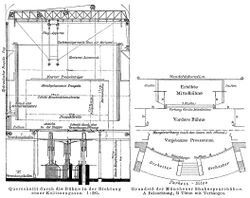

Prompted by the Ringtheater fire in Vienna, The Asphaleia Company took advantage of these technological developments to design fireproof stage machinery with a steel structure that was set in motion by water hydraulics (I.06). By the power of hydraulic machines, different segments of the stage could be extended as platforms, lowered, set in an inclined position and even set in a rocking motion to simulate, for example, the motion of a ship. Hydraulics also powered the overhead flying systems. All of these mechanisms required larger backstage facilities, higher fly towers, greater depth and width of stages, and a strengthened grid. One of the advantages of hydraulic power is that it runs very quietly and smoothly, adding to the sense of magical transformation – a return to the sensibility of the baroque stage, but on a far larger scale.

The Asphaleia design was first realised at the Opera House in Budapest (Q7696) in 1884 on the stage of the opera house, and then was installed in theatres all over the world. The Budapest system divided the stage into a grid, each with an independently controllable lift. The lifts were stacked, one upon the other, so the system could create both raised platforms high above the stage, and lower deep below stage level. The platforms could also rotate, to create angled levels – a more dynamically flexible system than had ever been seen on stage before.

At the Theatre Royal Drury Lane, London (Q7851), a system of two hydraulically powered stage ‘bridges’ were installed, covering the whole downstage area. Shortly afterwards, in 1898, an additional two bridges were installed, this time powered by electric motors, each of ten horse-power. Each of the four bridges was 40 feet by 7 feet. The term bridge, rather than platform or lift, is used to indicate the structures were supported at the ends only, so when raised above the stage the space below was completely clear. The downstage bridges had two independent hydraulic rams, one at each end. When the two rams operated at the same time at a constant speed, then the bridge rose or fell horizontally, but when the rams operated independently, the bridge could tilt, one end higher than the other. The rams were worked by pressurised water, supplied by the mains hydraulic supply of the mains of the London Hydraulic Power Company (Q30568) at a pressure of 800 lbs. to a square inch. The London Hydraulic Power Company was another crucial innovation for mechanised stages (and a variety of other industrial applications) in London – its network of 180 miles of pipes, buried just below the surface of the road, powered many of the West End’s safety curtains, as well as the revolves of the Palladium and Coliseum theatres. In winter, the water was heated to prevent it freezing, with the side benefit of melting the snow in the streets above.

As theatre entered the 20th century, it had gained the capacity to transform the stage, moving scenic elements on and off from the back, sides, below and above, to change the form of that apparently most stable of surfaces, the floor itself – all through hydraulic and electric power.